So you wake up on any given weekday and get into your morning routine. Maybe you get onto your Peloton bike for some workout. Sometimes you wear your Fitbit and go for a run. Or perhaps you grab a Lime scooter or Lyft bike to get to your office. Maybe you drive to the office in your Tesla. If you work from home, you can set up your Owl camera for meetings. What's an Owl camera, you ask? You were with me until the mention of Tesla, but not everyone's heard of the Owl camera.

Before becoming household names, Peloton, Fitbit, and Tesla were all hardware startups. Lime bikes have made a name for themselves, but not everyone still knows about them, especially if you don't live near a large urban area. Well, it's common for people to never even hear of Owl cameras. What is it about hardware startups that either catapults them into stardom or banishes them to linger in obscurity? From my journey through the rugged land of Silicon Valley hardware startups, I have learned a few things which I wish to share. This is the third article in my series on startups, and it comes on the heels of an exciting new energy storage IoT startup coming out of stealth, Lunar Energy.

"Hardware is hard to build, scale, and sell profitably." You have heard them say variations of this before, perhaps in a TechCrunch interview where an entrepreneur was lamenting, or maybe one of your colleagues shared their war stories. But why is it so hard? Discrete semiconductor components, "chips" in layman's terms, have been around for at least six decades. The software on these chips, aka "firmware," is written in C, a language that has been around since the 70s. The operating system a lot of their software runs on is "Unix-based," another veteran technology. It so looks like the ingredients are not that cutting edge. Oh, yea, these hardware startups also need to manufacture their products. Apple manufactures its products in China with Foxconn. One can call Foxconn, send them the designs, and they will manufacture them. Shouldn't that be straightforward? Evidently, it's not.

I want to shed some light on the typical blindspots of first-time hardware startup founders. I hope this article may help all the founders who aspire to build physical products.

A Founder's Journey for Building Commercially Viable Hardware

1. Parts, Components, and Complexity

So what does it take to build hardware? Although hardware can mean anything from auto parts to self-driving cars, from furniture to fitness bikes, from pet trackers to heart rate monitors, hardware startups are almost always building consumer electronics connected to the internet. Let's do an exercise where we get to conceptually develop a product as we go along. As with software, one often tends to build a clone of a popular app or website to learn the state of the art. For this exercise, we will be creating a Ring Camera clone. Ring (now an Amazon company) makes surveillance cameras primarily for residential use. Their cameras are small in profile, have night vision, are cloud-connected, and come with an App that helps you manage the video recording, set up motion alerts, etc.

So what do you need to build a Ring Camera? One of the best resources for hardware is iFixit teardowns. Here is the teardown for Ring Camera. Take a moment to scroll down to the very end to get a feel for the variety of components required to build a tiny, cloud-connected camera with merely a LED for UI.

It has a camera lens, an image sensor, and an image signal processor. It has a light sensor and an IR-based motion detector as well. It has a wake-on-sound microphone. It has a WiFi board, a processing board, and a Bluetooth board. It has a battery and a corresponding controller board. There are memory chips, flex connectors, RF shields, etc. Not to mention the plastic housing. Phew!

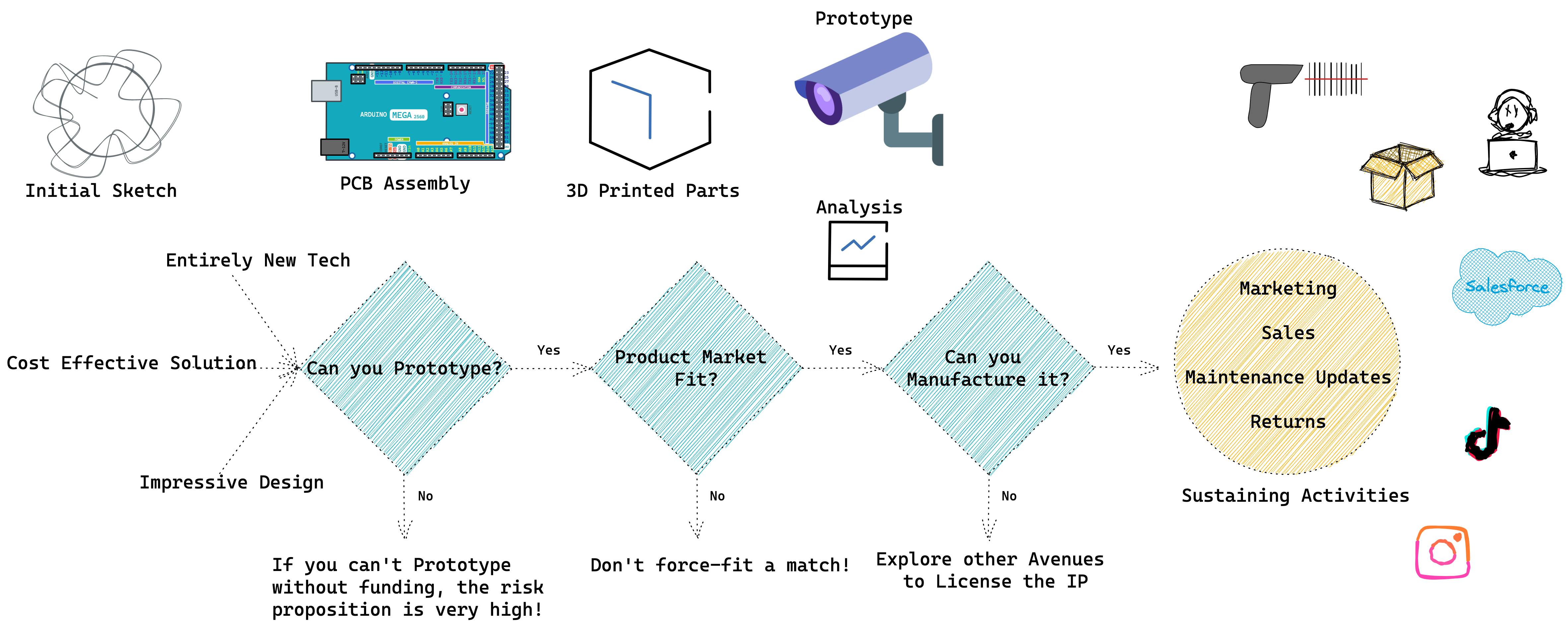

So, this is the first difficulty with building hardware: the complexity and the variety of components being put together. You start with a goal: "I want to build a cloud-connected camera." You need broad knowledge of sensors. You need to know about the communication technologies components use to talk to each other and the internet using WiFi or cellular. You need to understand power electronics. Finally, you need to select the proper processing or computing chips. But, you don't just jump to the final product. You get to it incrementally increasing your complexity and reliability. You prototype first; we'll talk about it in the next section.

2. From DIY Proto to Manufacturing

Up until the 2000s, before Arduino, Raspberry Pi or SparkFun existed, building consumer electronics as a hobby meant going to Fry's or RadioShack to pick up components. Scanning through data sheets, struggling through KiCad or similar software to design your PCB. Mercifully, you can now prototype electronics much faster and with a lot of guidance available on the internet.

But, unfortunately, this is where many founders make a fatal error. Founders are exciting beings. They are passionate about their ideas. If that idea turns out to be a physical product, they roll up their sleeves and get themselves a solder gun and a logic analyzer from eBay. They buy a bunch of "kits," aka development boards, for the Arduino or Raspberry Pi. Solder a few components on a breadboard. Then they get a 3D printer, print a casing, and cram the components inside the 3D printed shell. They are usually nifty with the coding aspect and can cook up firmware that does their MVP.

From here onwards, turning the DIY prototype into an actual shipping product is monumentally hard. Founders often go around in circles when they think they are moving toward their destination, just as Sam and Frodo thought they were doing on the way to Mordor.

Components are packed into a tiny space where they should not get too hot to stop functioning. They must comply with standards such as the FCC, and the components must coexist in a noisy RF environment inside and outside the device; careful antenna design and placement are critical. Further regulations could exist if the devices are used in a medical capacity. Every product is unique and has to get the applicable regulatory certifications to sell. Most first-time founders only hear about certifications after they hire an electrical engineer, and they have not accounted for this in their schedule (if they have one, that is).

It is well understood that iterative changes in hardware are to be avoided. Often, the principal designs need not iterate much from a successful pilot/prototype phase. Additionally, the software that runs on these devices, aka firmware, is not supposed to iterate as fast as software. This is because you can not upgrade devices over the air as often as you would like. Every startup learns, in its unique way, that the network costs, interruptions in functionality, and security issues make firmware release management a specialized field. As the name suggests, firmware must be extremely fault-tolerant, self-mitigating, and reliable. Problems in firmware can reboot the devices or put them out of commission, and more often than not, these painful issues crop up when your deployment reaches a specific volume. This means that your home unit tests on a DIY kit will not be able to benchmark or prove your software is ready for primetime. It would help if you had a continuous testing harness. Most founders only look for a firmware engineer when beta customers complain or if certification is pending or blocked, which is too late. Almost always, startups never hire a device QA engineer. Another mistake.

Manufacturing is a broad field. But as a founder, learning all about manufacturing is not advised or even required. However, the founder is expected to select the most appropriate contract manufacturer. A manufacturer with experience in building the type of product the startup has envisioned. In addition, the manufacturer needs to be comfortable taking on the initial low volume target of the startup. Yes, manufacturers require you to place orders for hundreds of thousands of devices to make it worthwhile.

The founder must vet manufacturers thoroughly, build trust, and continuously monitor their work. Founders should not delegate this critical piece to an employee, no matter the employee's position or experience. This is a significant business relationship, and the founder needs to own this connection. However, more often than not, founders either gloss over the manufacturing tech or, on the other extreme, they are off-hand except when signing the checks. Either way, the startup suffers.

So now you must wonder, is it even worth building all this hardware from scratch? Indeed, if there are kits available, we can use them. We can monetize the SaaS product that runs on the devices and use commodity devices. That, my friend, is not cost-effective. The kits come at a premium and will not necessarily cater to your increasing volume demands. It would be best if you had control over the supply chain so that you can build as many devices as you need on demand, which is why you need to manufacture.

3. Build vs Buy

Going back to our Ring camera exercise, some of the components used in building the Ring camera have been around for at least a decade, e.g. the TI MSP microcontroller or the IR motion detector. In consumer electronics, it is common to run into components that have a legacy. They are well documented and have many successful products built using them.

Oftentimes, physical products are built via the integration of legacy components. This is not always the case. I worked at a startup "Avegant" in 2016-2017. A quick glance at their website would tell you that they are building optics technology for Augmented Reality, or what is now popularly known as the Metaverse. This is a novel technology and needs researchers from the field to build it from the ground up. When building physical products, you may sometimes need to invent a novel component. (Note: This doesn't have to be a brand new chip, it may very well be a custom FPGA or DSP.) You will have to rely on academic research in the field of interest. Your startup might well be the first to bring a piece of tech from the field of research into commonplace gadgets. Big semiconductor firms already do this, and launch groundbreaking products, that later, find their use, e.g. the touch ID in the iPhone. I suggest that, as a hardware startup, you should lean on established semiconductor companies and material sciences firms for the innovation at the "component level," while you innovate at the "product integration level."

As a startup, though, you have to tread carefully between building and buying. Your product's uniqueness may not have to do with cutting-edge technology but rather with the physical design that makes it more accessible or cheaper. A lot of hardware innovation is about cutting costs, i.e., disrupting 10s of thousands of dollars' worth of products in the enterprise space and bringing them to consumers for 10s of dollars. Numerous home medical monitors of blood sugar levels are a perfect example of this.

Whenever a choice is presented between building vs. buying, weigh in the costs involved. Perhaps building a component may sound cheaper from a 10 thousand foot view, but first get a conservative estimate from your electrical or mechanical engineer. Ask them first how many weeks or months it will take for them in order to perfect a component or a design. Founders often take on more than they can chew, trying to build things that could have easily been bought. Sometimes it's because of the idealistic thought process that startups exist for the act of building. I would contest that startups are for problem solving. They are for providing products or services where either none exist or whatever exists is expensive and dated. Which brings us to the next aspect that brings down many hardware startups. Product-Market-Fit.

4. Product Market Force-fit

When you plan to sell the Ring camera we are building, you will be pricing it at a premium on top of the manufacturing cost, bill of materials (BOM) cost, certification fees, and engineering costs. Let's assume the customer plans to buy the camera even at a premium. However, in order to use it, they will need a cloud connection. A system for backing up videos, retaining them, and streaming them out to an app would require your startup to pay fees to an IaaS such as AWS. You surely can't charge for these fees upfront, as you typically pay for cloud infrastructure annually or monthly. So you make the Ring camera have a subscription. So, in order to use the camera after purchase, customers will have to subscribe to a monthly plan. This is not uncommon, nearly every consumer electronics out there today comes with a subscription plan. But therein lies a reduction in TAM because, unlike apps or software, customers expect hardware to be a one-time purchase cost that they incur. They expect to enjoy the hardware for a few years and then move on to the next latest and shiny gadget. A subscription fee on hardware feels "extra." The iPhone doesn't have a subscription fee for using the camera, but it does have a fee for iCloud. But they are Apple. They have built trust and brand recognition over the last 40 years. As a founder, take advice. Can you enter the same waters as Apple or Amazon as a young startup?

When founders first start building the hardware, they are passionate about the problem it solves. They are excited about the building part of it and have a business plan to sell it. They have a total addressable market (TAM) mapped out. They have a competitive price and a launch date in mind. The founders demo the prototype to the investors, and let's say investors love it and fund it! However, when the founders go to the manufacturers, they soon learn that the volumes required for them to sell at a profit are often in the millions of units sold per year. To make sales of that tune in the hardware space and to do that within your launch year is what differentiates winners from losers. Sadly, though, founders and analysts often overestimate the need for a product. e.g. Perhaps we don't need drone deliveries, as there are plenty of human delivery agents in the most profitable urban areas. Drones do stand a use in underserved rural Africa where there isn't the infrastructure needed to carry medicine to those in need. But is that going to meet the volumes needed to make it profitable? Perhaps not.

The volume game is why the product market fit finding is so much more crucial for hardware startups. Not only do a lot of people have to love your product, but they also have to be willing to pay for it upfront and, in most cases, also subscribe to a plan, e.g., Peloton's fitness classes. There are no "freemiums" in hardware. There is also no ironclad product-market fit formula either. If your product feels right in the hands of the consumer or in their home, it will be sold. You can do as many A/B tests with the looks-like and works-like prototype as you like, but you will only find out if it sells when it hits the shelves. If I can take a page out of Tesla's book, in the short term, they offer customers a cool electric car that does 0-60 in under 5s. In the long term, they give customers a reason to help the environment by reducing emissions. It's this kind of marketing that brings customers to hardware brands, a promise of short-term cool and excitement as well as long-term greater good. Holding a piece of science fiction level technology is very important to people, they just don't know it!

5. Sales, Marketing, Ops, and ARR-the Four Horsemen of the Apocalypse

In the previous section, we talked a bit about marketing. A lot of founders have taken the route of socializing as well as funding their hardware ideas via crowd-funding, i.e., KickStarter or IndieGoGo. It's been sadly observed that the ideas get plagiarized because they are in public space. The plagiarizers are not impacted by IP laws and are able to reverse engineer the startup's product, putting the replica on shelves sooner than the startup can even take off. I would suggest keeping your product under wraps, demoing it to investors under an NDA, and getting the funding you need to get to manufacturing as described in prior sections.

A few startups go with the celebrity endorsements. Keep in mind, it may come at a high cost. The cost can be either cash or equity, or both! Viral marketing through social media is perhaps not very effective either. If your product is ready, factory is primed and waiting for orders, perhaps you may take the route of media PR. But if your product still has some details to finish and is not yet ready for primetime, then I would suggest double down on dogfooding, beta testing. Learn as much as you can and improve your product. Once it starts shipping as a result of your marketing, no matter the volume, you will start getting online reviews. If your reviews point out issues, it will hurt the sales. So the lesson here is to avoid pre-mature marketing campaigns. A note about event marketing at CES or MWC: they are effective at gaining partners but also risk leaking your secrets to potential competitors. A large company can easily replicate your idea and bring it out in volume without stepping on your IP!

Channel sales are a very effective way to get your product into stores without much marketing. Stores with significant foot traffic get enough eyes on your product. After your product is out there, put out unboxing videos and respond to comments on YouTube, Reddit. This way, you would gain trust from potential customers. DTC, or Direct To Consumer, is preferred by investors as it cuts the middleman. However, many a DTC startups have struggled and lost value. I would suggest you find investors who have a store presence (preferably physical stores). Physical products need to be demoed and felt by the potential buyer, as old-fashioned as that may sound.

As your product starts moving, start to measure the Returns vs. Orders metric. Yes, you are going to get returns. If your returns are growing, get to the pain point and root cause with urgency. It could be a flaw in the manufacturing process or a software bug. You will need to establish operations for hardware returns, monitoring bug reports, and managing software upgrade rollout. All of it is pretty specialized and tailored for your product e.g. if you are building smart ovens that weigh 10lb, the kind of return process you need is different from that of a small consumer electronics like a fitness tracker. Unlike the massive community of customer-success and CI/CD Dev-ops, hardware startups are often in the dark and have to rely on advisors from major electronics firms. Ensure that you have project managed this piece properly with [SOPs] (en.wikipedia.org/wiki/Standard_operating_pr..) laid out firmly.

Finally, a word about [ARR] (saasoptics.com/saaspedia/arr). The past two decades have primarily observed the rise of SaaS startups. SaaS startups are measured based on ARR. In fact, their per-IPO valuation is on average 13x their ARR. This has, however, biased investors into expecting growing ARR from hardware startups. Physical products need to attain significant volume before becoming profitable, and it can take a few years. As I mentioned in earlier sections, slapping a subscription service to a hardware, often is detrimental to sales. Try to bear the costs of the cloud piece without transferring them to the customer. Gain trust, reduce returns, and get repeat customers. If your customers are SMB or enterprise, getting repeat sales with bigger orders is a huge deal. You can eventually start charging for "premium" features, e.g. unlimited cloud storage of video for the camera. This is why it is crucial to find an investor who can be a channel partner. Don't fall for the DTC trap. It sounds cool, but you are not Tesla (yet).

Finally, a mention of SaaS companies dabbling in hardware. It is great that they have a main revenue-generating machine, and they are perhaps exploring IoT or similar hardware to diversify. This can either go well, they succeed in creating successful hardware products, like Amazon did with Lab126. But it is also easy for this hardware division to become a "startup" within another startup or company. When that happens, neglect, lack of allocation of sufficient resources necessary for building hardware, lack of ops support, can all make the hardware venture a pipe dream. If you are a SaaS founder who wants to do hardware, I would advise against it. An entire ecosystem needs to be built for provisioning device clients and consuming their data. If it's a novel technology, it takes consistent R&D effort. Leaving the effort half way is common, and is utterly wasteful.

This is it for today's article in the world of startups. Until then, keep building. Everybody wants a piece of sci-fi tech in their hands (or on their head), they just don't know it!